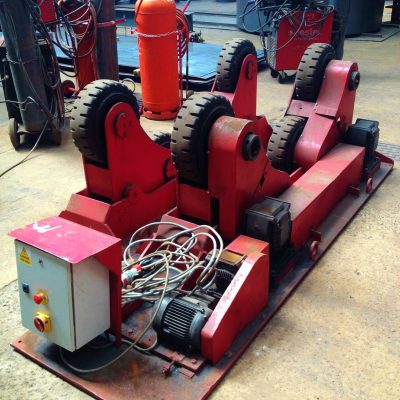

Self-Aligning Welding Rotators

SAR Self-Aligning welding rotators are designed to quickly auto-align and pivot on 2 shafts, in order to easily accommodate a range of vessel sizes. The SAR means there is no need for timely wheel center adjustment, unlike Conventional Welding Rotators, where the wheel bogie frames must be setup each time to suit a pipe diameter.

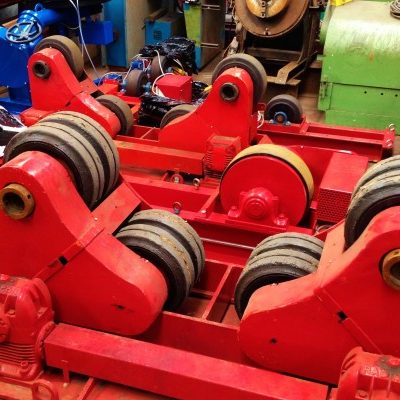

The other major advantage of Self-Aligning Rotators, is that the multiple wheel design per unit, means the weight distribution massively reduces pressure points, and eliminates silo denting on thin wall steel. SARs are usually always used on 5mm / 6mm / 8mm thin wall stainless tanks. The top wheels on a 4-wheel SAR rotator, means the wheel captures the vessel higher up, cusping the pipe side wall, allowing tubes to maintain their shapes, preventing them from bellying out.

If load spread is essential, we also have Self-Aligning rollers that have double wheels (4x 2 per unit), which reduces the pressure points by half again, and then half again with another SAR support idler under the cylinder (if it will fit).

SAR turning rolls can be used for all pipe turning jobs, and are used as handling equipment, designed to position pipe, pressures vessels, silos, storage tanks, and turn all things cylindrical, allowing for controlled automated welding.